Forest Products

Forestry industry mainly focuses on producing finished or semi-finished products from wood raw material by changing its form through various processes (cutting, paring, shredding, adhering, pressing, impregnating, etc.).

Forest Products Industry

The forestry industry has many subfields supporting each other and includes the timber industry, plate industry (coating, plywood, blockboard, particleboard, fiberboard), pulp and paper industry, parquet, woodwork, furniture, prefabricated structure production, musical instruments, wooden and all other products. The forestry industry has relations with various sectors, such as wood glue and chemical substance production sector, construction sector, decoration, wood craftsmen, sellers of petroleum products, automotive sector, energy, profile producers, forest-village cooperatives, cement production sector, metal industry, paint, polisher, insulation tools, glass, and glass-like tools, door and window woodworks and hardware.

Driving systems that are durable against long and challenging working conditions are needed in almost all production processes executed in the forestry industry. PGR Drive Technologies meets the demands of the sector with its products that are capable of working at variable speeds with/out brakes and with rigid and strong bodies and locking mechanisms.

Forest Products Solutions

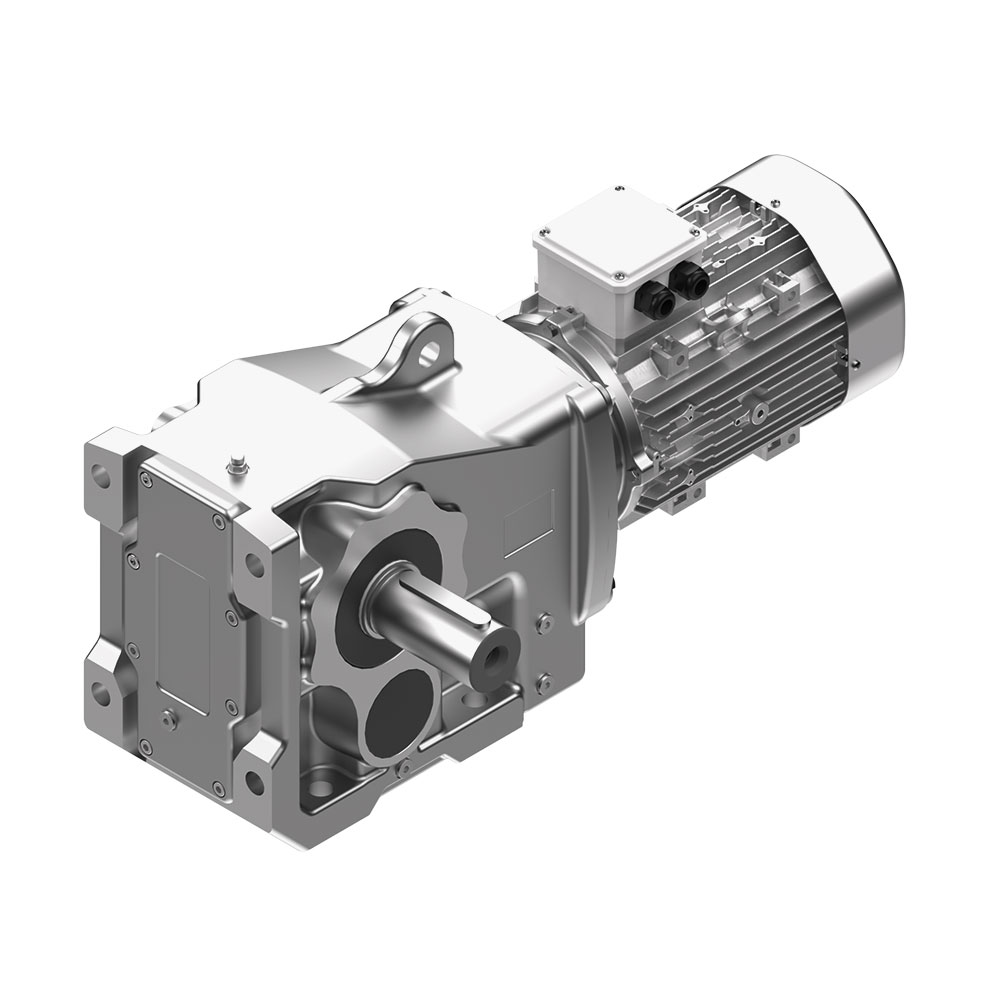

PKD Series

It may be the drive solution in various conveyors used for heavy load transfer where movement is to be directed at 90°.

- Helical bevel gear units with 90° input and output axis range.

- Casing with feet, flange F options.

- A rigid structure in case.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options may be provided (Coupled motor, IEC, PAM, W, Servo motor connected, ...).

- Different output options available (Solid shaft, Hollow shaft, With shrink disc, ...).

- Different mounting accessories available (B5 flange, B14 flange, Torque arm and Platforms,...).

- Bodies are manufactured from sfero (GGG 40-50) and peak (GG 20-25).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.

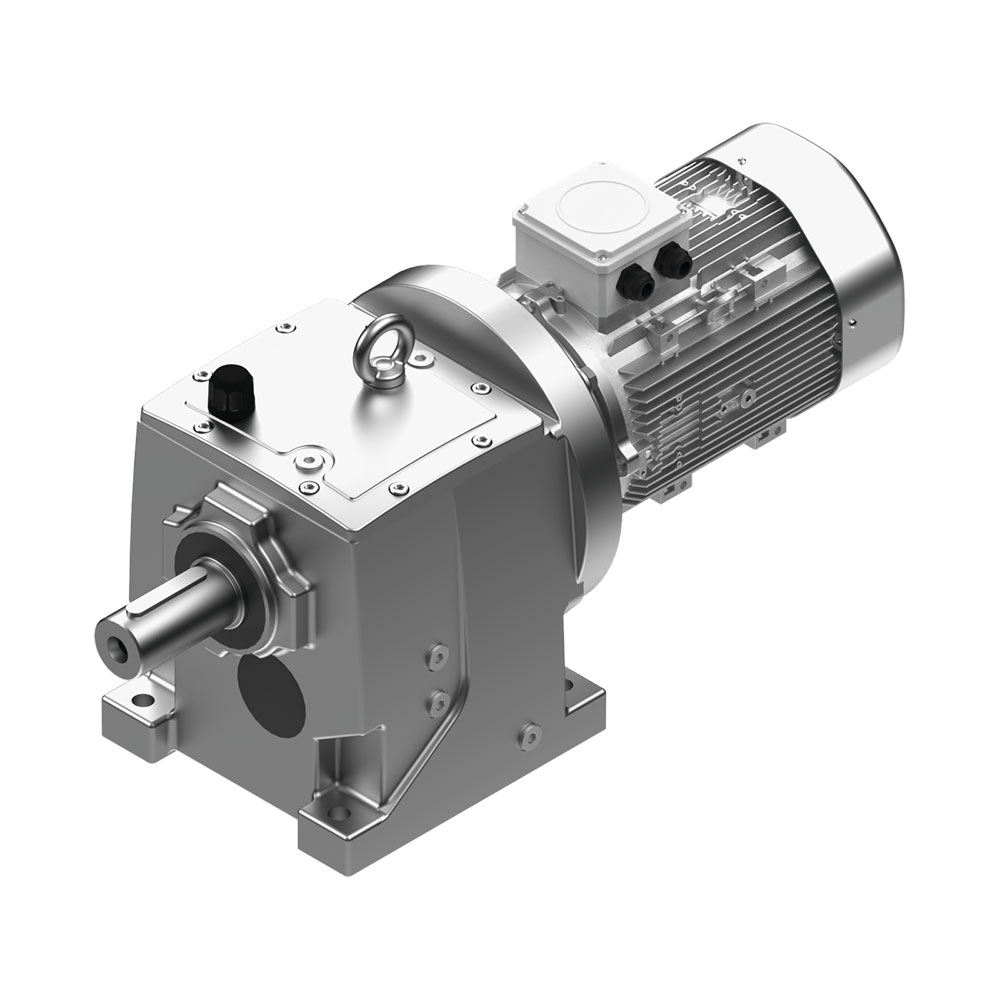

PA/PF Series

These series which are provided in foot- (PA) and flange (PF) mounted options serve up in drive systems that need wide reduction ratio and maximum 26900 Nm of output moment.

- Helical gear units with parallel axis input and output.

- Casing with feet, flange F options.

- A rigid structure in cases.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options may be provided (Coupled motor, IEC, PAM, W, Servo motor connected, ...).

- Different flange measurements may be provided in B5 mountings.

- Cases are manufactured from sfero (GGG 40-50) and peak (GG 20-25).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.

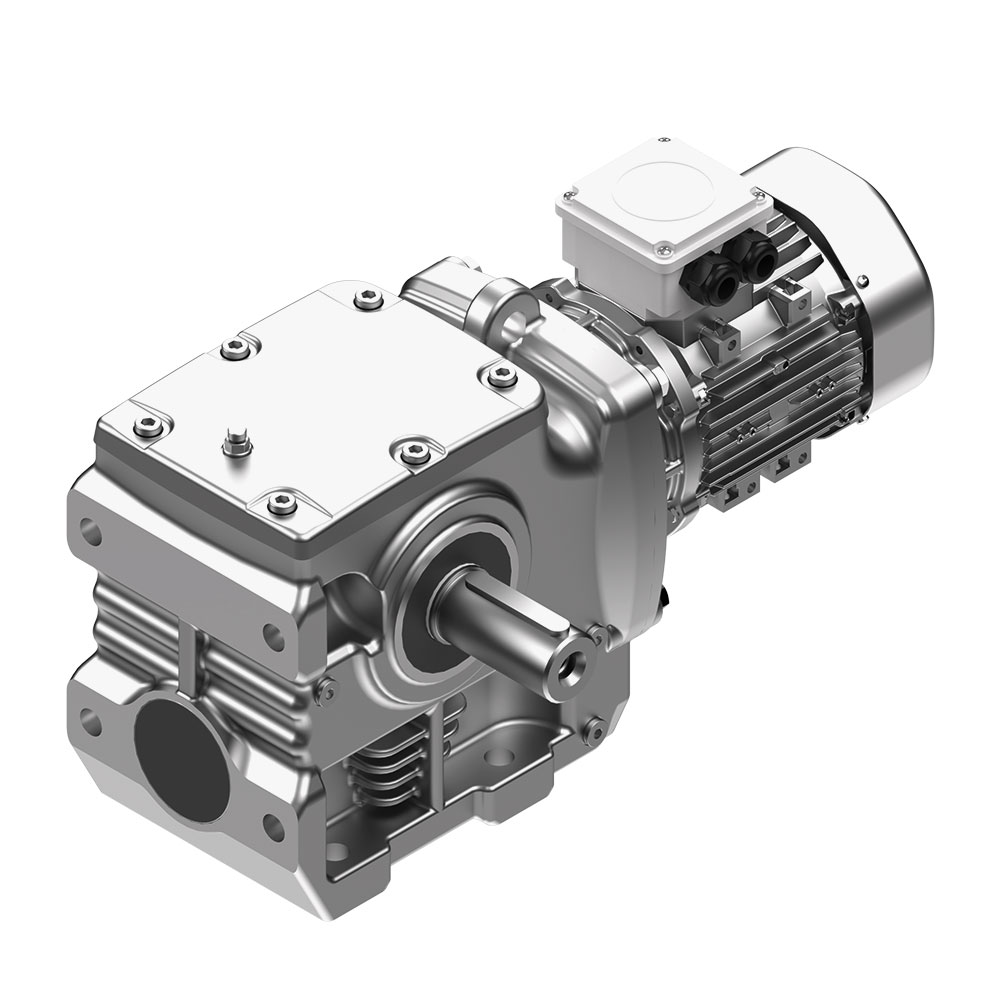

PSH Series

PGR Drive Technologies provides solutions with PSH series products for driving and positioning carriage platforms.

- Helical and worm gear units with 90° input and output axis range.

- Casing with feet, flange F options

- Rigid case structure and suitable for heat transfer.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options may be provided (Coupled motor, IEC, PAM, W, Servo motor connected, ...).

- Different output options available (Solid shaft, Hollow shaft, With shrink disc, ...).

- Different mounting accessories available (B5 flange, B14 flange, Torque arm, ...).

- Bodies are manufactured from sfero (GGG 40-50) and peak (GG 20-25).

- Helical gears are made of cast and 21NiCrMo2, screws are made of 16MnCr5 case-hardening steel, worm wheels are made of CuSn12 Ni2-C bronze material.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.

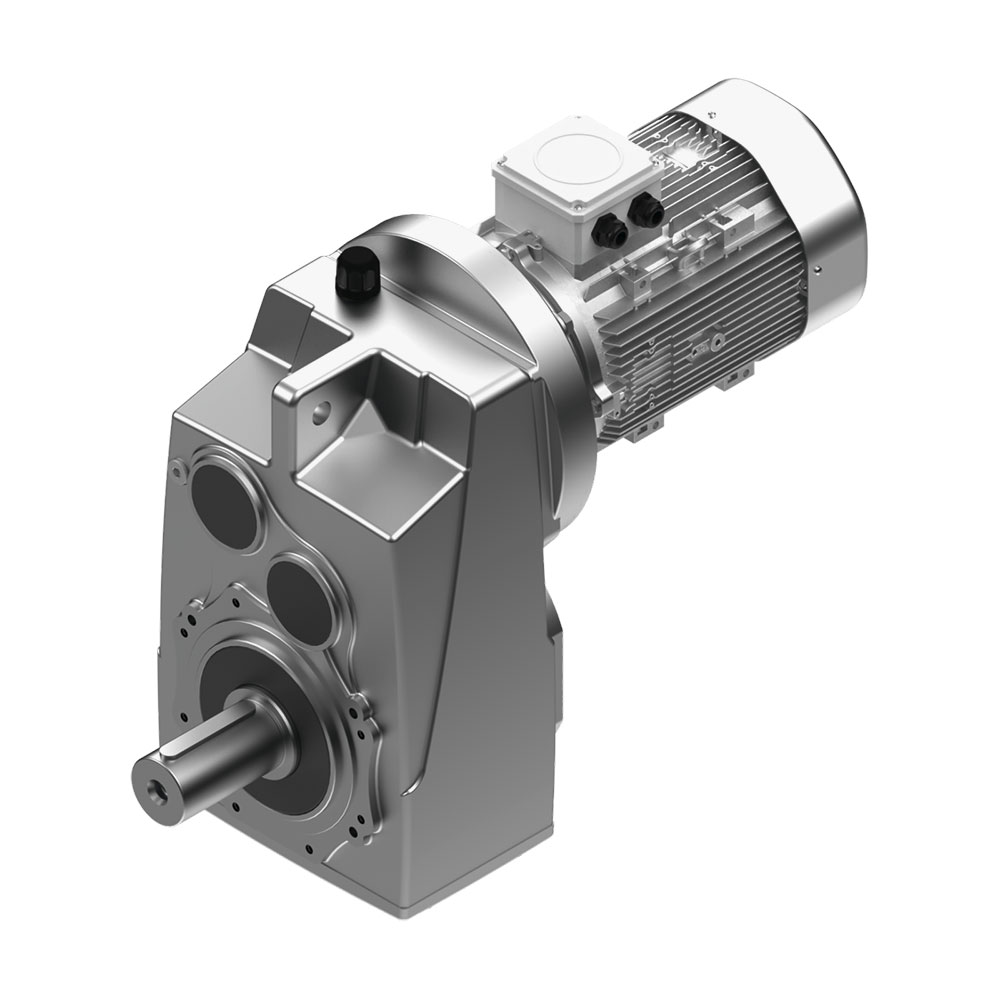

PD/PM Series

PD / PM series parallel shaft mounted gear units produced with hollow shaft or solid shaft are commonly preferred in conveyor drive systems.

- Helical gear units with parallel axis input and output.

- A rigid structure in case.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options may be provided (Coupled motor, IEC, PAM, W, Servo motor connected, ...).

- Different output options available (Solid shaft, Hollow shaft, With shrink disc, ...).

- Different mounting accessories available (B5 flange, B14 flange, Rubber buffer for torque arm, ...).

- Cases are manufactured from sfero (GGG 40-50) and peak (GG 20-25).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.

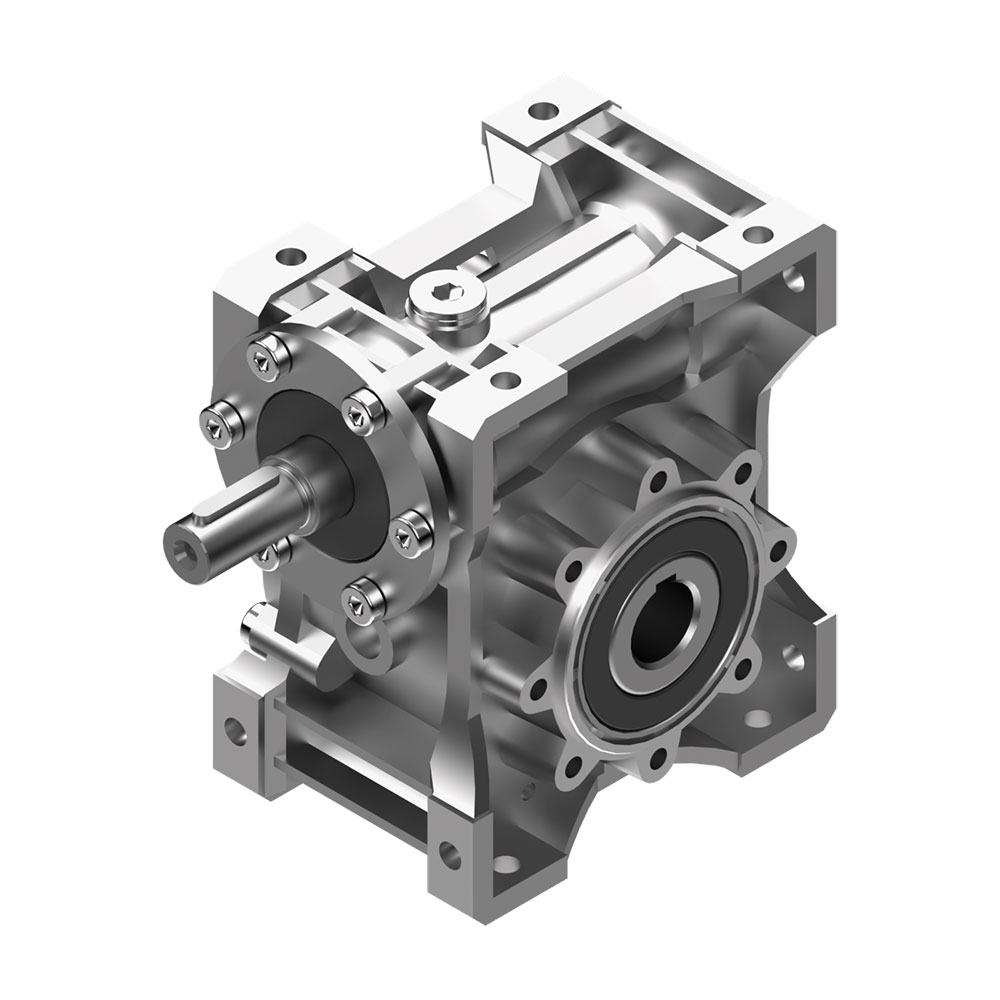

PMRVPLUS / PRVPLUS Series

Offered for drive systems with low moments and regular loads, worm gear units stand out with their light, modernly designed bodies with high strength, as well as silent operation.

- Worm gear units with 90° input and output axis range.

- Foot- and flange- mounting available with a single case.

- Rigid case structure and suitable for heat transfer.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options available (PAM B5, PAM B14, ...).

- Different output options available (Solid shaft, Hollow shaft, ...).

- Different mounting accessories available (B5 flange, B14 flange, Torque arm, ...).

- Worm screws are made of 16MnCr5 case-hardening steel, worm wheels are made of CuSn12Ni-C bronze material.

- Cases are made of ADC-12 aluminum injection up to 105 body case and peak cast (GG 20-25) for over 110 body case.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.