Construction

Processes of carrying, processing, loading and unloading of many products in various types and weights are routine, but important works done daily at construction sites. From construction inputs such as sand, gravel, cement, etc. to steel reinforcements, various construction materials are used during construction process. Structure of buildings may be made of reinforced concrete or steel construction. Various driving systems are required during or after residential, highway, railway, bridge and dam construction.

Intense and high power consumption is required in carrying construction materials at sites with conveyors, cranes, elevators, etc., preparing and shaping concrete and steel constructions.

With silent, rigid body and safe gear unit series, PGR Drive Technologies provides various solutions for construction sites and architectural buildings. With driving systems with brake/brakeless, lock mechanism, shrink disc, variable-speed options, it meets needs of the sector.

Construction Solutions

PCD Series

The use of cycloid series gear units in the power transmission field meets the demands for compactness, high gearing, small size and product reliability.

The most important feature of the PCD series, which has a different design from traditional gearboxes, is that the drive elements transmit the movement by rolling over each other, instead of the friction movement of the gears with each other as in normal gears.

- Units with parallel axis input and output.

- Connected with feet, body options

- The case has a rigid structure and is suitable for heat transfer.

- It is offered with a solid shaft.

- System strength calculations are made in accordance with DIN, ISO and NIEMANN standards.

- Different input options can be offered (Motor coupled, PAM, W, C-face).

- Discs are made of 100 Cr6, bodies are made of GG25 material.

- There are different mounting positions; horizontal and vertical

- Single stage up to case 612 are lubricated with grease and bodies between 613 and 620 are lubricated with oil bath,

- Double stage 607/07…618/10 bodies are lubricated with grease and 616/11…627/19 bodies

- are lubricated by oil bathing.

- Special requests of the customers may be considered.

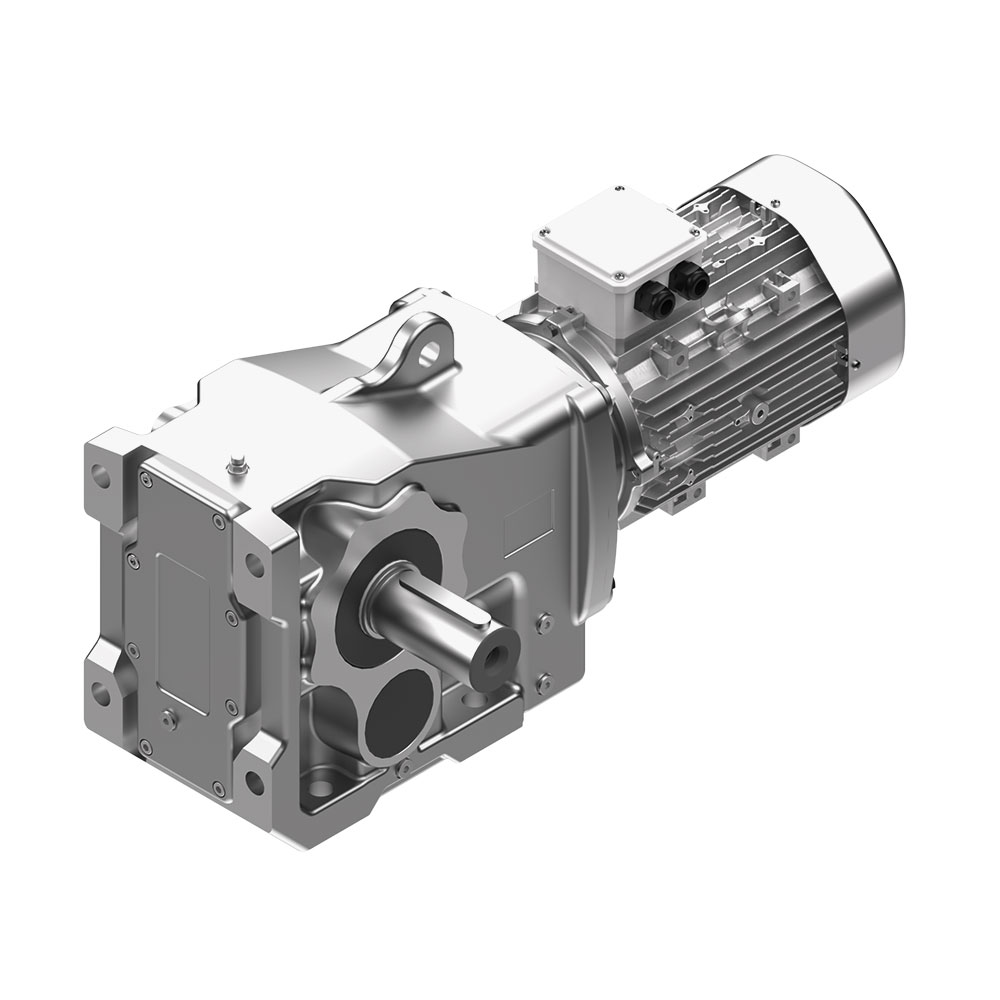

PKD Series

It may be the drive solution in various conveyors used for heavy load transfer where movement is to be directed at 90°.

- Helical bevel gear units with 90° input and output axis range.

- Casing with feet, flange F options.

- A rigid structure in case.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options may be provided (Coupled motor, IEC, PAM, W, Servo motor connected, ...).

- Different output options available (Solid shaft, Hollow shaft, With shrink disc, ...).

- Different mounting accessories available (B5 flange, B14 flange, Torque arm and Platforms,...).

- Bodies are manufactured from sfero (GGG 40-50) and peak (GG 20-25).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.

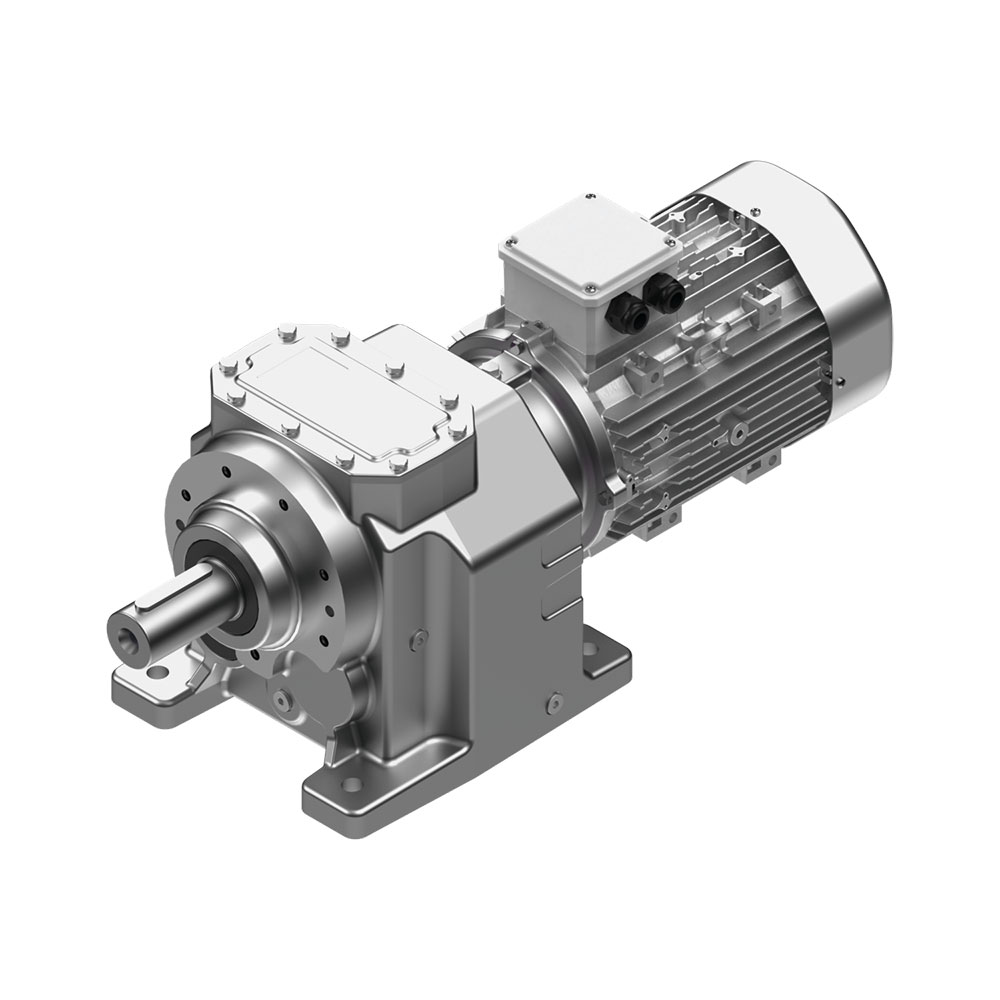

A/F Series

With its compact body and easy mounting advantages, PGR Drive Technologies provides solutions up to 8600 Nm moment with its A/F series released to the market.

- Helical gear units with coaxial input and output.

- Casing with feet, flange F options.

- A rigid structure in case.

- It could be provided in solid shaft form.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options may be provided (Coupled motor, IEC, PAM, W, Servo motor connected, ...).

- Cases are manufactured from sfero (GGG 40-50) and peak (GG 20-25).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.

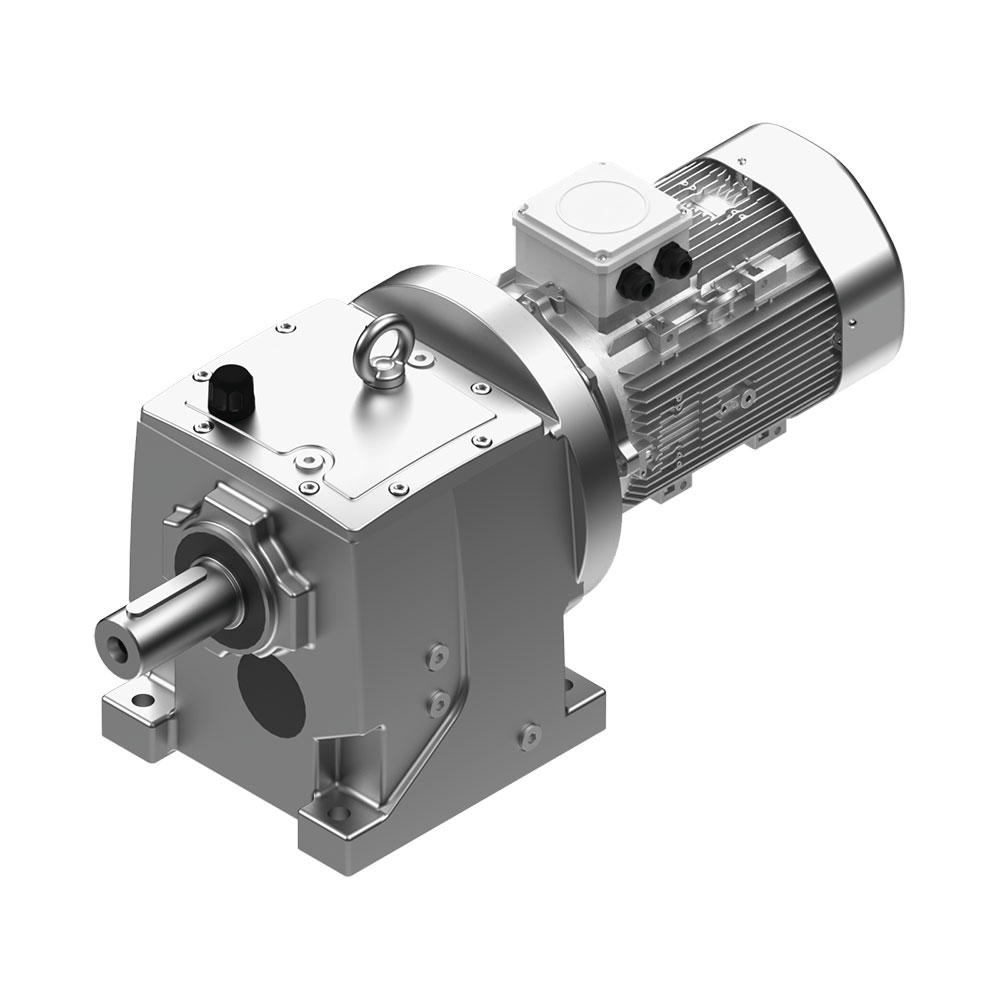

PA/PF Series

These series which are provided in foot- (PA) and flange (PF) mounted options serve up in drive systems that need wide reduction ratio and maximum 26900 Nm of output moment.

- Helical gear units with parallel axis input and output.

- Casing with feet, flange F options.

- A rigid structure in cases.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options may be provided (Coupled motor, IEC, PAM, W, Servo motor connected, ...).

- Different flange measurements may be provided in B5 mountings.

- Cases are manufactured from sfero (GGG 40-50) and peak (GG 20-25).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.

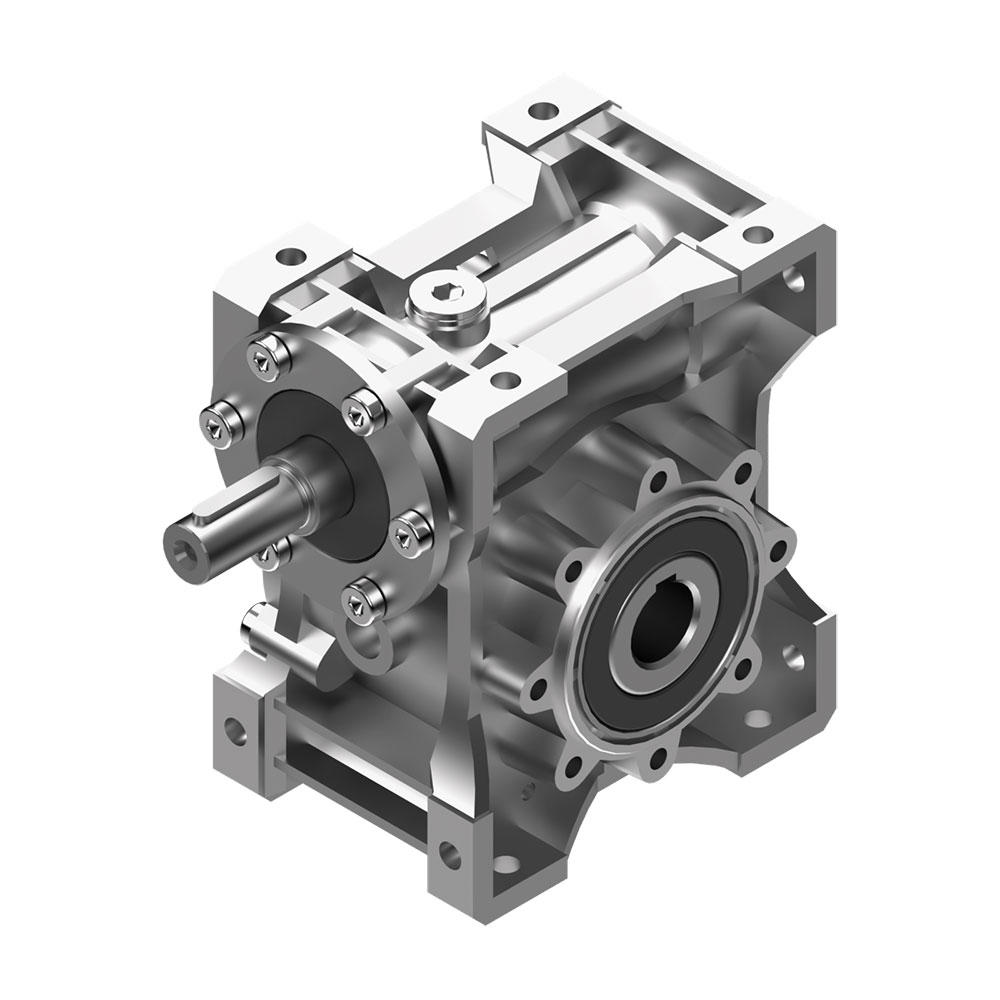

PMRVPLUS / PRVPLUS Series

Offered for drive systems with low moments and regular loads, worm gear units stand out with their light, modernly designed bodies with high strength, as well as silent operation.

- Worm gear units with 90° input and output axis range.

- Foot- and flange- mounting available with a single case.

- Rigid case structure and suitable for heat transfer.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options available (PAM B5, PAM B14, ...).

- Different output options available (Solid shaft, Hollow shaft, ...).

- Different mounting accessories available (B5 flange, B14 flange, Torque arm, ...).

- Worm screws are made of 16MnCr5 case-hardening steel, worm wheels are made of CuSn12Ni-C bronze material.

- Cases are made of ADC-12 aluminum injection up to 105 body case and peak cast (GG 20-25) for over 110 body case.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.