Crane

Cranes are efficiently used to lift loads and carry them from one place to another. Cranes can be used in in-plant carriage systems or on vehicles.

Cranes are able to carry and place loads multi-directionally and sensitively with specially-designed drive systems. With brake and driving control equipment integrated thanks to synchronized operation of crane and trolley, solutions with high operation success and high safety considerably contribute to efficiency of factories.

PCS series products provided by PGR Drive Technologies have lifting capacity from 1 ton up to 60 tons and comply with FEM – ISO standards. In addition to use with double-speed (2-12 poles) motors that have IP55 protection class, they offer perfect driving with frequency inverter. Our crane gear units with low corrosion and silent operation features are available in aluminum (EN-AB-46100) and cast iron (GGG 40-50) options.

Also preferred in industrial applications, PH/PB series gear units can be used for lifting processes at torque rating up to 480 000 Nm. These bodies ensure maximum safety in high power needs and operating conditions.

PGR Drive Technologies provide solutions with parallel shafted PD/PM series and bevel PKD series to ensure gantry and bridge movements in cranes securely and effectively.

Crane Solutions

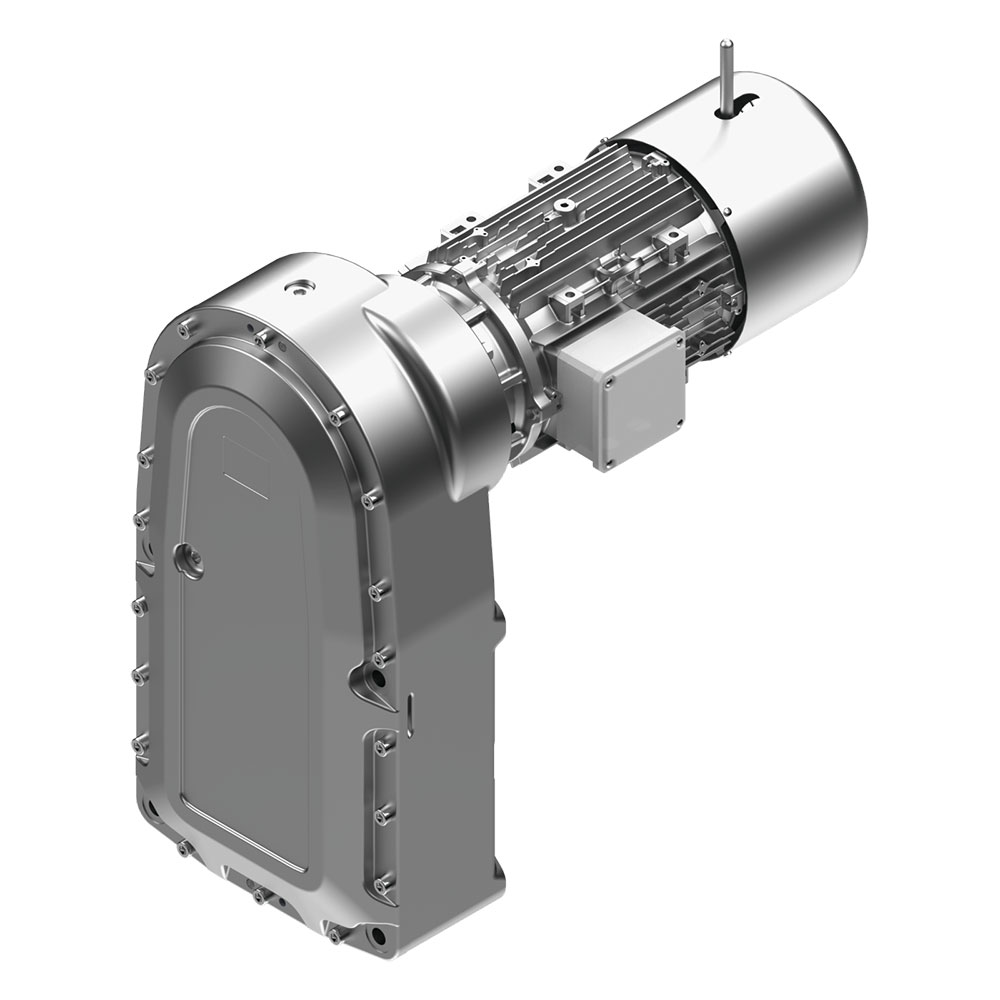

PCS Series

PCS series gear units of PGR Drive Technologies serving up to 60 tones of capacity are optimum solution partners for crane industry thanks to their silent, compact bodies and easy maintenance features.

- Helical gear units with parallel axis input and output.

- A rigid structure in case.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options may be provided (Coupled motor, PAM, Servo motor mounted, ...).

- Output shaft may be splined in accordance with DIN 5480-82 form and drum flange may be provided as output shaft accessory.

- Motors used are double speed (2-12 poles) or single speed (frequency inverter) and have IP55 protection class.

- Extra fan application is recommended for 2-12 pole motors.

- Cases are manufactured from aluminum and cast iron (GGG 40-50).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.

PZ Series

The suitable scope of speed reducer is as follows:

- The rotation of high speed shaft should not be more than 1500 rpm;

- The circumferential velocity of gear tranmission should not be more than 20 m/sec;

- The temperature of work environment should be -40-45°C. If it below 0°C, before start, the lubricating oil should be pre-heated to above 0°C. This speed reducer can be run at clockwise and counterclockwise direction.

Characteristics

- The gear is made of high strength low carbon alloy steel through carburization and quenching. The hardness of tooth surface may reach to HRC58-62. All gear adapts NC tooth grinding process, high in accuracy and good in contact performance:

- Highly tranmission efficiency: single stage, more than 96.5%; double-stage, more than 93%; Three-stage, more 90%;

- Smooth and stable in run, low noise;

- Compact, light, long life, high bearing capacity; Easy to disassemble, inspect and assemble.

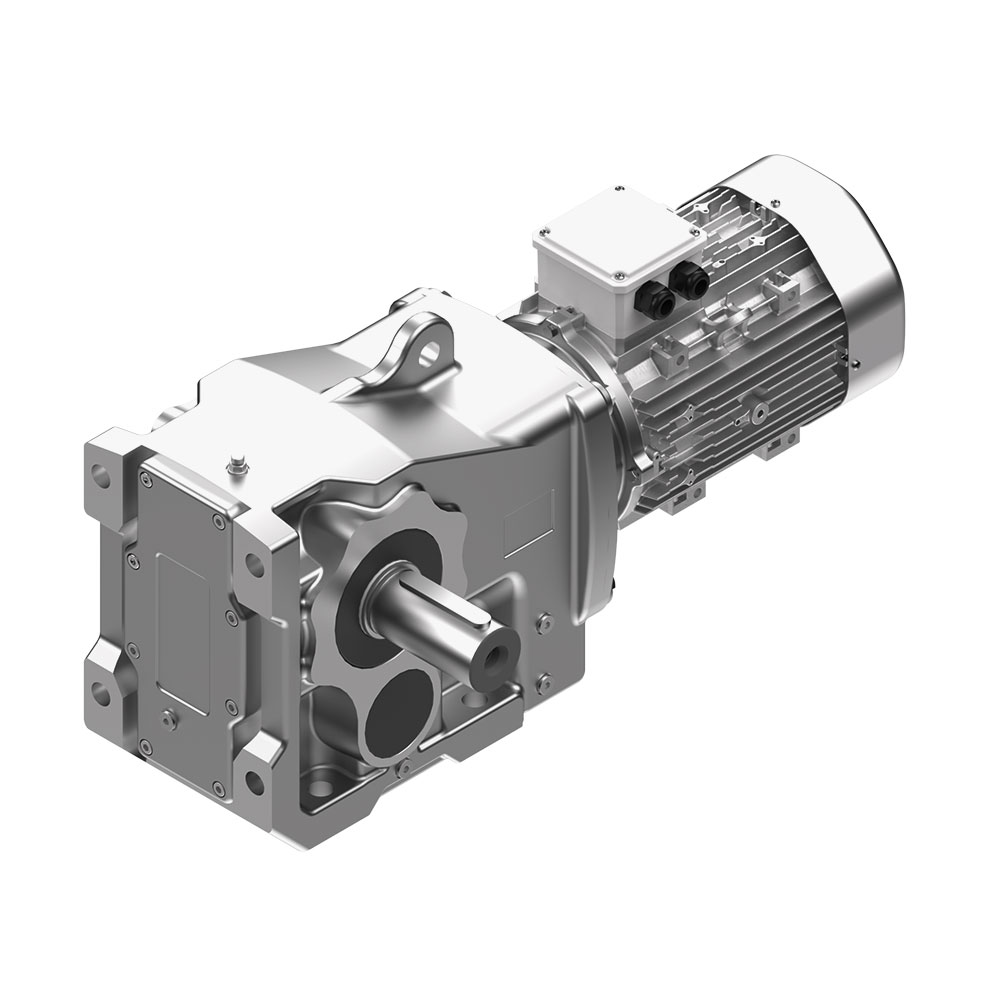

PKD Series

It may be the drive solution in various conveyors used for heavy load transfer where movement is to be directed at 90°.

- Helical bevel gear units with 90° input and output axis range.

- Casing with feet, flange F options.

- A rigid structure in case.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options may be provided (Coupled motor, IEC, PAM, W, Servo motor connected, ...).

- Different output options available (Solid shaft, Hollow shaft, With shrink disc, ...).

- Different mounting accessories available (B5 flange, B14 flange, Torque arm and Platforms,...).

- Bodies are manufactured from sfero (GGG 40-50) and peak (GG 20-25).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.

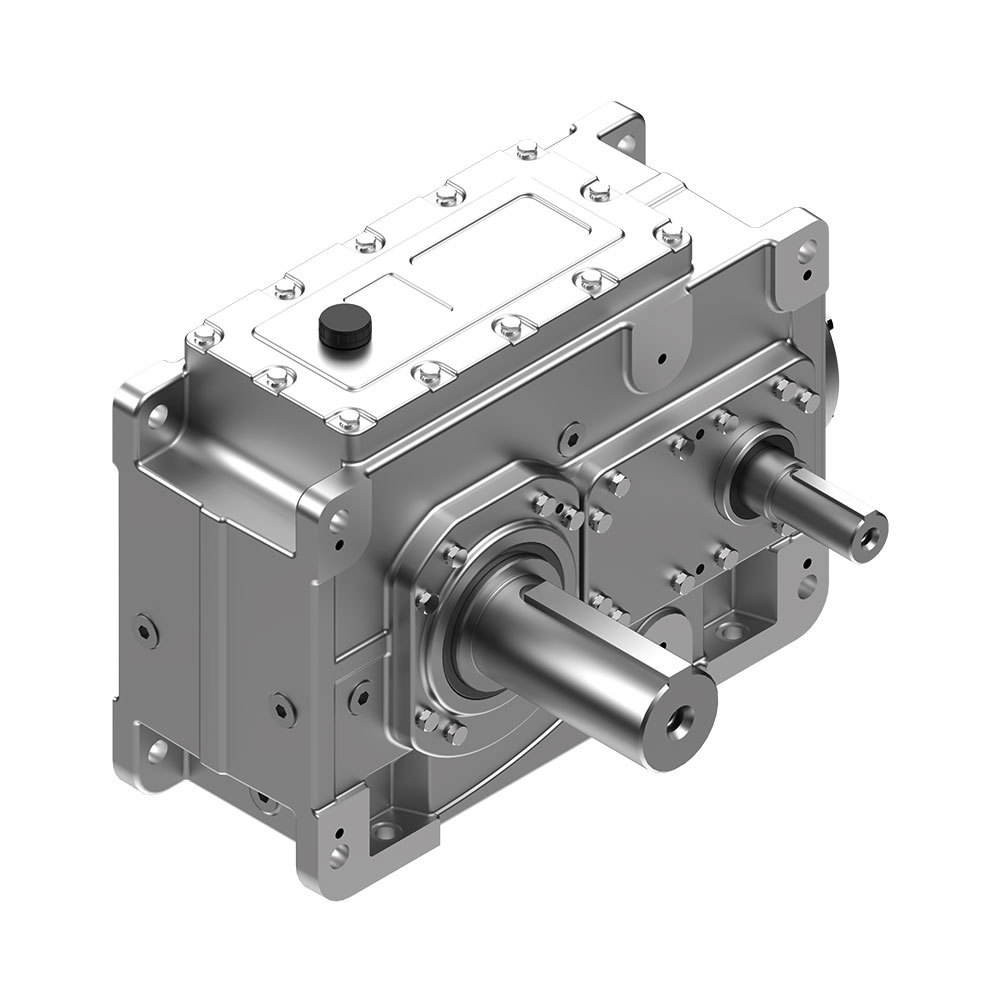

PH/PB Series

Industrial type gear units operate especially under heavy working conditions, have rigid case, bear high moments up to 480000 Nm and stand out with silent operation and easy maintenance features.

- Helical - bevel gear units with parallel axis input and output or 90° axis angle.

- Casing with feet, flange F options.

- A rigid structure in case.

- Gear units used to meet needs for high power under heavy working conditions.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options available (IEC, W, ...).

- Different output options available (Solid shaft, Hollow shaft, With shrink disc, ...).

- Different mounting options available ( B5 flange, Torque arm platform,...).

- Cases are manufactured from sfero (GGG 40-50) and peak (GG 20-25).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.

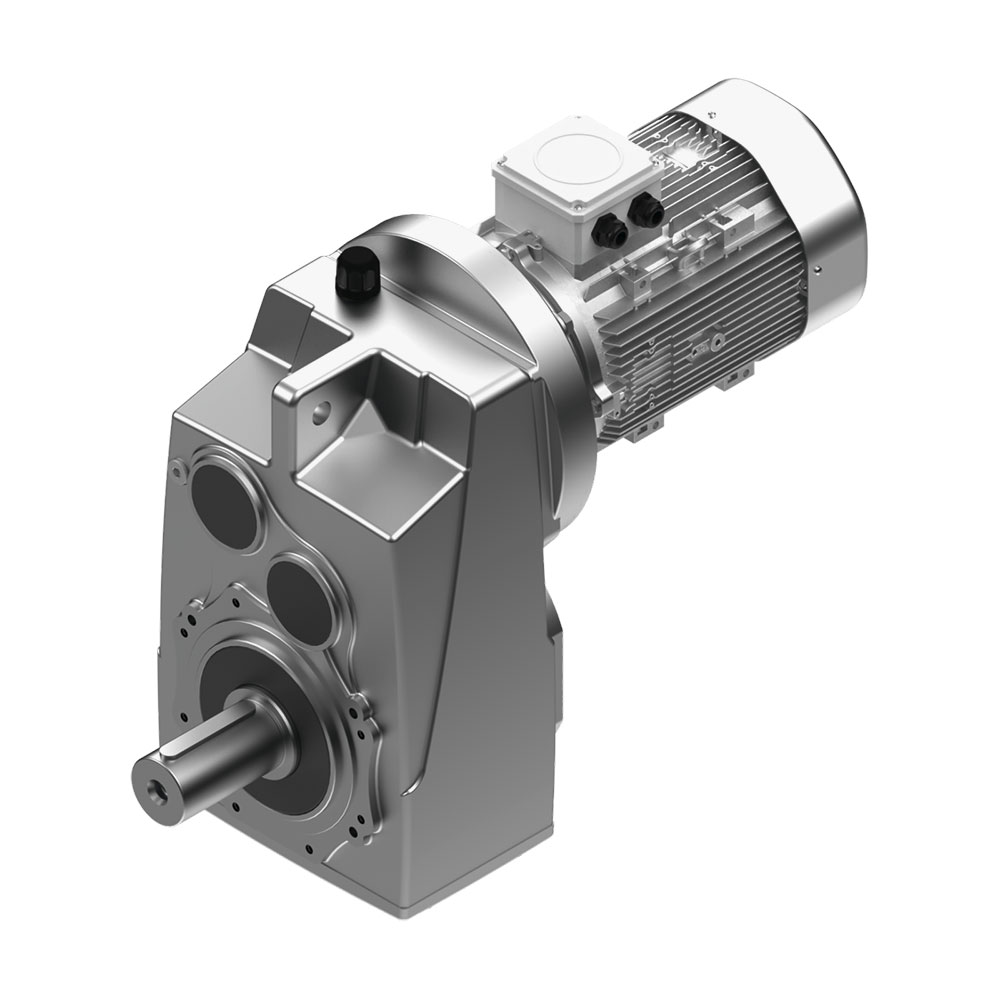

PD/PM Series

PD / PM series parallel shaft mounted gear units produced with hollow shaft or solid shaft are commonly preferred in conveyor drive systems.

- Helical gear units with parallel axis input and output.

- A rigid structure in case.

- System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards.

- Different input options may be provided (Coupled motor, IEC, PAM, W, Servo motor connected, ...).

- Different output options available (Solid shaft, Hollow shaft, With shrink disc, ...).

- Different mounting accessories available (B5 flange, B14 flange, Rubber buffer for torque arm, ...).

- Cases are manufactured from sfero (GGG 40-50) and peak (GG 20-25).

- Gears are made of cast and 21NiCrMo2 case-hardening steel.

- High-quality bearing and sealing components are used.

- Special requests of the customers may be considered.